The impeccable timing behind quantum dot’s impressive colors

June 20, 2025

10 min read

Nanosys’ system for precisely tuning quantum dot crystals has unlocked previously impossible colors and brightness.

Written by Adam Kovac

Illustrations generated by AI (inspired by Torres de Satélite, by architect Luis Barragán & artist Mathias Goeritz).

Great color starts with perfect timing. At Nanosys, breakthrough control over quantum dot growth allows for pinpoint wavelength tuning, unlocking brighter displays, richer color volume, and surprising new uses from agriculture to cosmetics.

Timing is everything, the saying goes, and it applies to a lot of things. In football, a half second too early, or too late, and the receiver misses the catch. In love, meeting the right person at the wrong time can result in the one that got away. Even the birth of the universe needed exquisite timing, as the particles that would go on to form planets and galaxies and humans had to explode outward in just the right way to avoid gravity sucking it all back into a singularity. So it should come as no surprise that the key to the best colors scientifically possible comes back to impeccable timing.

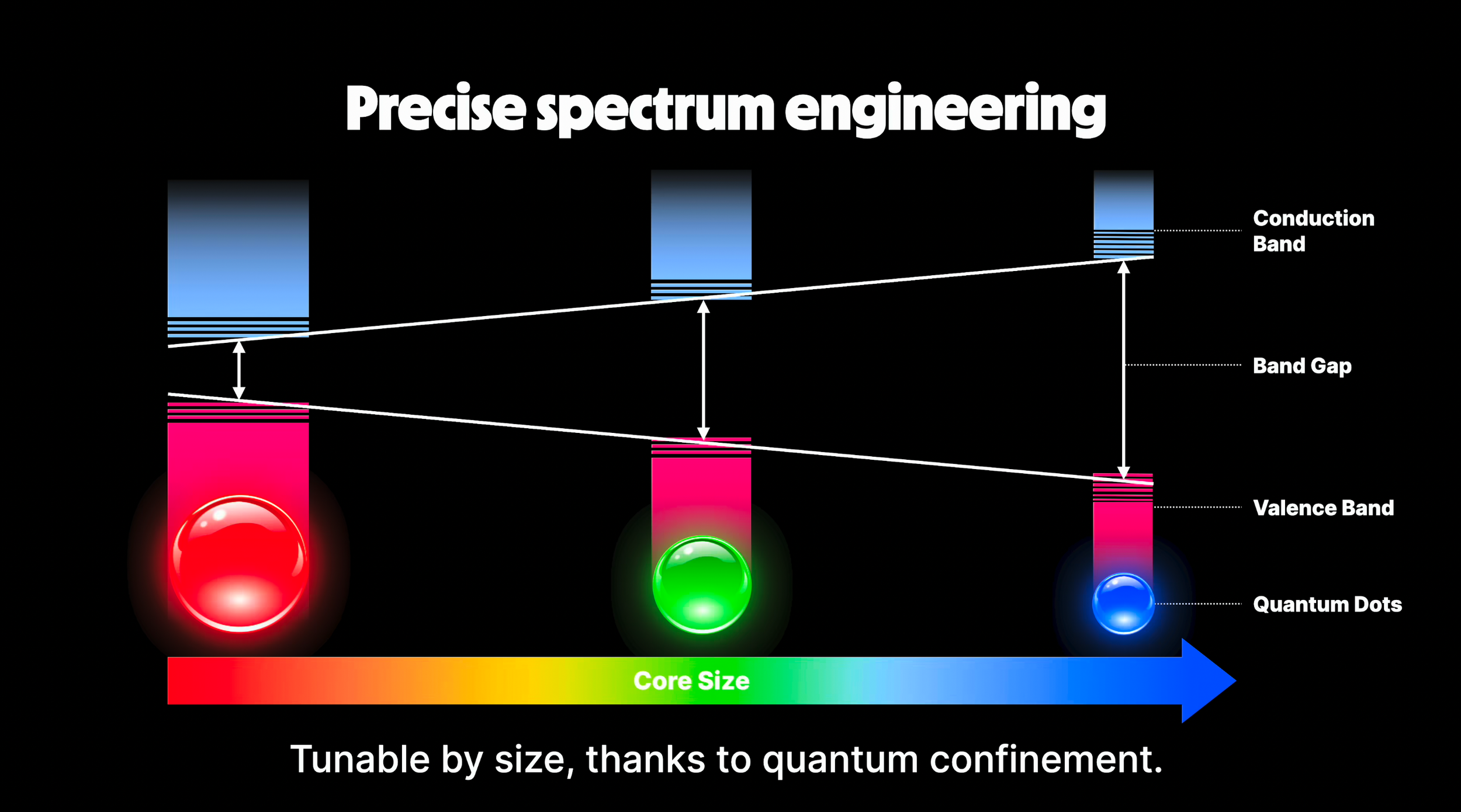

While quantum dots are semiconductors, they’re made in a very different way from the computer chips that are normally associated with that word. The dots are nanocrystals, and Nanosys has worked hard on a method of growing those crystals that can produce an incredible array of colors. The secret, explains Zhongsheng Luo, the company’s General Manager of Product Development and Vice President of Sales, is in controlling the precise size of the dots. The company’s technique for that level of exactitude lies in how long those crystals are allowed to grow.

“That's basically based on the thermodynamics of crystal growth,” he says. “If you monitor the whole growth, which we can do in real time, the crystal becomes bigger and bigger. That means, as an example, if it's 10 minutes, it’s 530 nanometers, so that's how we control that.”

"While the initial calculations can be determined using an empirical curve, Luo says that the process has gotten so advanced that “We actually don't even simply rely on that curve,” he says. “We rely on real-time measurement from an in situ feedback system to make it the same every time. With such real time monitoring, we can greatly reduce the tolerance, or the variation of the wavelength.“

The process has been perfected to the point that a Shoei engineer can input a specific wavelength of light they want the crystal to produce, and, by shining a short wavelength light on the crystals as they grow and measuring the peak wavelength, the production system can automatically stop the growth at the exact time it hits the target color.

“By tuning this wavelength, we can precisely achieve the color target that the display maker is looking for,” says Luo. "Not only that, we can also perfectly match the color filter of the display panel such that it gives the best brightness at a desirable color gamut.”

That brightness matters. As Luo observed, on televisions, brightness plays a big role in consumer choice. Brightness, he says, is “what killed plasma.”

"Looking at a plasma next to an LCD on a relatively bright showroom floor, people chose LCD every single time as the high brightness made LCD look much better than plasma, even though the plasma might look better in darker, more typical living room environment,” he points out.

Being able to tune the quantum dots with such precision has another added benefit. As Luo explains, the higher color purity allows for a higher color gamma, or a more efficient usage of bits while encoding and decoding an image. When images aren’t properly gamma coded, too much information can be dedicated to aspects that are imperceptible to humans. Quantum dots allow screen manufacturers to fine tune their tech far easier than was previously possible.

For traditional phosphor technology, when you change the wavelengths, it will need a new material, what is most likely to happen is the full-width-half-maximum may be broader in the beginning, so people need to spend a lot of time to try and tune it down right,” Luo explains. “That itself causes a lot of work. Secondly, the reliability may not be the same as the existing products. Now, they need to work on that as well. So it takes a lot of time to rein in, not only the optical properties, but also the stability to make sure its comparable with the existing products.”

Ultimately, the ability to finely tune quantum dots opens up new levels of color not just because of the range or the brightness, but because of how those two concepts combine.

Increased luminance allows the differences between different hues of the same color to shine through. In real life, it’s the hue of a banana, not the color, that allows you to tell whether it’s ripe or overripe. A conventional display can’t show you that level of detail, but one using quantum dots can literally give you images that look good enough to eat. According to Luo, the dots are capable of generating 30 to 40% more color volume perceivable by humans than more traditional technology.

That sort of purity can be the difference between nice images, and images so visceral and real it can make you feel like you’re right up against some of the most spectacular phenomena on Earth. Take, for instance, a volcanic eruption.

“If you look at a picture, it may not be as impressive as if you saw it in real life,” says Luo. “The difference is, if you look at the color coordinates, they are all well within the reproduction capability of a normal display, but because brightness is another dimension of the human perception of color, that gives you a different feeling. If you have a display that can reproduces a very bright lava, it gives you the feeling of the heat, as it conveys that kind of reality to your brain."

That's the other important part: quantum dots can bring not only more color, but also the color at the right brain level, and that is critical to human perception.”

If all this talk about watching a movie showing a volcanic eruption can elicit the same effect as being near one in person (albeit with far less chance of your shoes melting), it’s backed up by scientific studies. In tests run by Dolby, an audience was examined with thermal cameras while watching content on a quantum dot display and, during a scene where a fireball was shot at the screen, they saw that blood vessels in the audiences’ faces dilated, as if they were expecting to get hit by the flames: an involuntary physiological response it’s possible to not only emotions through the screen, but actual sensations in a viewer’s body.

While bright, vivid colors are gorgeous in and of themselves, the benefits of wavelength tuning and quantum dots is every device makers’ favorite word: efficiency.

In some places, such as Europe, the power efficiency of devices like televisions are regulated by law. Those laws are so stringent that advanced televisions, such as those with 8K or microLED displays, are severely restricted. Even in situations where there’s no legal aspect, getting bang for your buck power-wise can be important. Consumers expect laptops, for instance, to have a healthy battery life, and don’t want binge watching their favorite TV shows to lead to surprises when their electrical bill arrives.

Get the latest from Nanosys every Monday at 10:00am.

“You care about a one hour difference, you care about a 10 percent power saving,” says Luo. “I think the general societal trend is that people do pay more attention to the efficiency of the devices they're using. With quantum dot technology, we are working with that trend and helping our customers achieve the best efficiency they can. It's always good to have a better efficiency than a worse efficiency.”

That holds true not just for computer screens and television sets. The unique wavelength tuning made possible by quantum dots also has applications in agriculture and even in the green energy revolution. Luo pointed out that the quantum dots can be tuned to produce light in frequencies that some plants are highly sensitive to, promoting faster and more efficient growth and yields. That has uses not only here on Earth, but could even be taken to space, as global space agencies vie to build Moon bases and send humans to Mars. In both cases, growing food for the astronauts would play a vital role in making these missions logistically feasible.

“That's one area we can use to get a benefit for human beings, because we have more and more population, but we have limited land,” he says. “We are also looking at things that are solar energy related. We can basically transform one spectrum that cannot be used today, or can be used but with very low efficiency, to a spectrum that has a highly efficient conversion rate or utilization rate.”

There are less grandiose, but potentially commercially lucrative uses. Some goods degrade when exposed to particular light frequencies. Luo points to perfumes as an example, where the bottles used for packaging must be designed to prevent ultraviolet light from ruining the product before it can even be used. New European laws prevent manufacturers from implementing UV stabilizers in the perfume itself, presenting a conundrum for packagers. Bottles incorporating quantum dots can be tuned not to emit, but absorb, those frequencies, allowing for packaging that is both protective and attractive to consumers. It could even be possible in the near future for quantum dots to find their way into the automotive realm, resulting in cars that either have eye-catching paint jobs that aren’t currently possible, or even change color depending on the time of day.

“There are many other applications that we are exploring with our partners today,” says Luo. “It can be exterior design, or even for human cosmetics. There could be some kind of medical or health benefits. Those are all coming. It's just that many of them are in a very early stage, so we are still working with our customers to try to explore those areas.”

The technology has become so advanced, Luo says, that the main challenge no longer lies in generating or finely tuning the dots, which can now be produced by the ton, in quantities of crystals that number in the trillions. Instead, it lies in only producing the specific wavelengths needed by customers in the correct proportions.

“The customer may not need all the wavelengths equally, right?” says Luo. “The challenge for us in terms of manufacturing is, how do we manage such that we can control our manufacturing costs at a reasonable level? Other than that, technically, I don't think there’s really any challenge.”

The problems of implementation, he adds, have all been solved. Still, not just any company can pull it off. It required years of R&D and refinement by the Shoei team to get to this point.

“It doesn't mean it's easy, right?” says Luo. “We are so used to it, so we don't even think about that anymore today.”

Gain clarity on Quantum Dot technology.

Excited about Quantum Dots but unsure to apply them to your tangible product? Our team answers your big questions about this tiny technology.