How Nanosys engineers use ligands to create the perfect quantum dot

June 11, 2025

7 min read

Quantum dots can have tiny flaws. The answer lies in even smaller molecules called ligands.

Written by Adam Kovac

Illustrations by João Marcus Felix

Ligands play a vital role in synthesizing quantum dots, but also in maintaining their stability, allowing for screens that can last for 100,000 hours.

It’s easy to take advanced technology for granted. Looking at a television screen, you can forget the sheer amount of research that went into making the images possible. That includes displays incorporating quantum dots, the production and implementation of which pose considerable engineering challenges.

That’s where David Olmeijer, Nanosys’ Director of QD Formulations, comes in. While Olmeijer plays an integral role in coming up with the processes that make the vivid color of quantum dots possible, he didn’t start his science career with them in mind. Rather, he studied polymer chemistry. It was a fortunate decision because, as he points out, “pretty much everybody out there needs polymers. Just about every kind of technology, at some level, is going to be incorporating something with a polymer.”

That includes quantum dots. The dots made by Nanosys find themselves incorporated into a variety of substances, like films and inks. That, it turns out, is a perfect fit for a polymer chemist.

“I've been able to be involved in a bunch of technologies that are perhaps outside of my core expertise but I've been able to leverage my expertise as a result,” says Olmeijer.

It was about 10 years ago that I joined Nanosys and it's a very interesting way of leveraging nano materials, nano composites, in a way that can make interesting products for a variety of applications.”

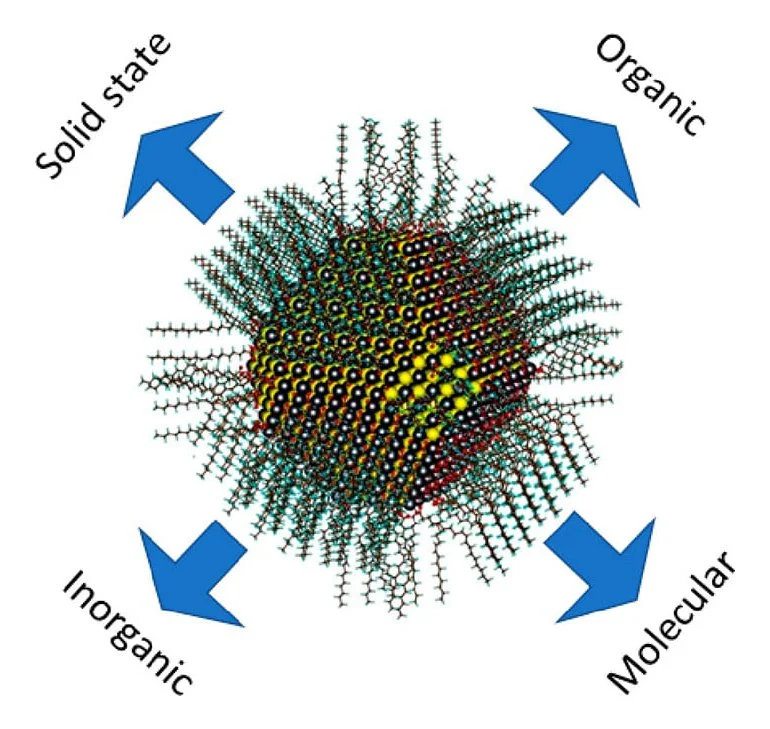

Olmeijer is thinking big about the effects quantum dots can have on the consumer market, but to get them to function as they should, Nanosys engineers need to first think very, very small. Quantum dots are extremely tiny, measuring just a handful of nanometers across. For reference, a hydrogen atom is around 0.1 nanometers, and a DNA double helix is around two nanometers wide. When working on objects that miniscule in scale, scientists can run into all kinds of unpredictable problems. For quantum dots, one of those issues is high surface to volume ratio.

“Quantum dots are semiconductors, and they're very, very, very small, and what happens is that, because they're very small, they have a very high surface to volume ratio, which means that the electronic properties of the surface are going to play an outsized role on the overall materials’ properties,” explains Olmeijer. “Any defects that you have on the surface are going to play a rather significant role in the efficiency and the performance of the quantum dots themselves.”

What that means is that because of their size, the electrons found in the quantum dots can migrate from the interior to the surface. If there are defects on the surface, those electrons can get stuck there, which can ruin the properties of the dots that allow for such vivid and bright colors. If these imperfections were allowed to let stand, the dots would either not work, or they would work far more inefficiently.

“We're talking about molecular defects,” says Olmeijer. “You're talking about, on the individual atoms of the quantum dots, if you have one atom there that doesn't have the right number of bonds, now you've suddenly got a surplus of electrons or a surplus of holes and the electronic properties of the quantum dot are impacted as a result.”

The answer to this particular particle-sized problem lies in organic molecules called ligands. Their exact composition can vary depending on which atoms appear on the surface of the quantum dots. What they have in common is that the ligands perform two important functions. The first is, particular kinds of ligands can be used to fix whatever ails a particular dot. This isn’t a matter of going in and fixing individual dots as they display flaws (that would be a nightmare, given their size), but rather of how the dots are birthed. Ligands are present in several of the precursor materials that are used to synthesize quantum dots. Those materials are carefully measured out and then exposed to precise temperatures. As the quantum dots appear and grow, they are essentially swimming in a sea of ligands, which allows the molecules to attach themselves to the dots from the very beginning, fixing problems during the synthesis process.

If there's an excess of electrons on the surface of the quantum dots, then the ligand that comes in can combine with those electrons,” says Olmeijer.

“If there's a deficit of electrons on the surface, then a different kind of ligand comes in, and it can donate electrons to help fix that defect. As a result, the quantum dot electronic structure is complete, and then it can operate more effectively.”

In other words, because the ligands plug holes where electrons would be able to escape, the quantum dots become more stable. The ligands also prevent other molecules, such as oxygen, from infiltrating a dot, which would also affect stability. The ligands don’t just allow the dots to perform their function, they allow them to do so for a longer period of time. Products using quantum dots can offer consumers more bang for their buck before wearing out.

We have strategies for making the quantum dots stable enough so that your TV screen can last 100,000 hours or more!” says Olmeijer.

Given the average American watches 2.67 hours of television a day, that would mean roughly a century of Netflix before the screen wore out.

But the ligands don’t just act as a fixing agent. They also play an integral role in making the dots as useful as they are. As Olmeijer explains, the ligands’ molecular structure is what enables the dots to be mixed into different solutions. That opens up a wide range of applications beyond the displays they’re known for.

“Ligands are organic molecules, so they have a head and they have a tail,” he explains. “There's the head that binds to the quantum dot and does all the work of fixing the defects. But then there's the tail, which is usually a fatty acid, or something along those lines. And what the tail does is, it will allow you to process the quantum dots in different solvents, in different polymers, in different resins.”

Unfortunately, synthesizing the quantum dots with these fatty acid ligands present leads to another issue that requires solving. The ligands used in that process are hydrophobic, and are only able to fare well in oils. This may not be a bad thing, if the polymer the dots will be incorporated into is itself meant to be hydrophobic. But if there’s a use case that requires the dots to be soluble in alcohol or other liquids of that nature, it can cause malfunctions.

Get the latest from Nanosys every Monday at 10:00am.

“A lot of extremely hydrophobic polymers, such as acrylates and whatnot, have some degree of polarity to them,” says Olmeijer. “The hydrophobic ligands are insufficient in making them compatible with those kinds of polymers or monomers. Therefore you need to introduce some polarity into your ligand shell, in order to allow your quantum dots to be compatible with them.”

This can be done, Olmeijer explains, with even more ligands.

“What we can do here is, we change the ligands,” he says. “We replace the original ligands that are there with different kinds of ligands that allow the quantum dots to be soluble in other kinds of things.”

One example of this process is inks. The potential usefulness of the unique color properties of quantum dots in inks is fairly obvious (for instance, a quantum dot-based inkjet printer), but many inks are based on molecules that are slightly polar, and would be hostile to the dots. Olmeijer explains that Nanosys has a process that can rectify this issue.

If you're going to have your quantum dots dissolved in an ink, you pretty much have to do something where you're changing the polarity of your quantum dot surface,” he says.

“That's just talking about the world of polar organic solvents. If you really wanted to get the dots soluble in water – if you have a water based application – then you have to go even further. You have to, you have to really put a lot of polarity and perhaps even some electrochemical charge on the surface of your quantum dots.”

The number of ligands available for use in quantum dots is still growing, as people like Olmeijer continue making advances in chemistry. (“You can create new molecules all the time,” he enthuses). That sort of innovation means the future of quantum dots is quite literally unimaginable. Olmeijer noted there are currently some obstacles in the way before they can be used to create improved VR and AR displays, both with the ligands and with the dots themselves. But with committed researchers hard at work, the future's looking bright.

“It's hard to say how far this can take us,” he says. “All of these things have their logical limits. But the world of quantum dots is definitely trying to get into more and more applications, and people like me, who are doing the ligand side of the quantum dot synthesis, are going to have to do our part to help get that over the line.”

Gain clarity on Quantum Dot technology.

Excited about Quantum Dots but unsure to apply them to your tangible product? Our team answers your big questions about this tiny technology.